Digital Production Management

As early as 2003, Roadage has been applying the digital production system which is composed of ERP, PDM and CRM these three parts. With the help of systems, our management level is always leading in our industry.

TOP

Contact

Manufacturer of Core and Key Brake Components for Commercial Vehicle Brakes

As early as 2003, Roadage has been applying the digital production system which is composed of ERP, PDM and CRM these three parts. With the help of systems, our management level is always leading in our industry.

With the development of the factory, Roadage began to be troubled by low efficiency because of the continuous expansion of the scale. However, as early as 2003, we knew the ERP system during an overseas visit and started to apply more than ten years ahead of other peers. With the help of ERP, Roadage entire business process becomes transparent and all aspects of production, materials, storage and transportation are tracked, which improves our efficiency and production capacity.

Since 2005, Roadage has been using the PDM system to realize the digitalization of paper document and manage the technical data from the product concept, engineering and design, to die-making, forging, processing, heat-treatment, machining and etc. Nowadays, we accumulate a large amount of technical data about vehicle braking products and apply them in manufacturing.

Using the CRM System for 10+ years, Roadage can truly grasp the requests of clients from different countries and districts in a short time. It helps us to record and accumulate information from thousands of clients about local special road conditions, climate and many other factors related to the standards and requirement of products. What we know is not only vehicle braking products, but buyers' thoughts, preference and demand.

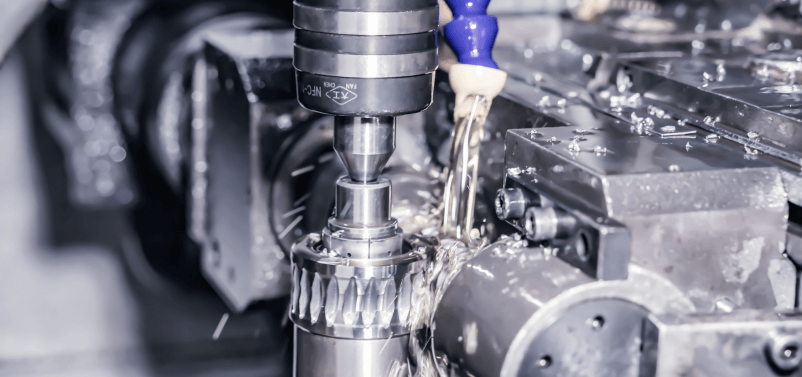

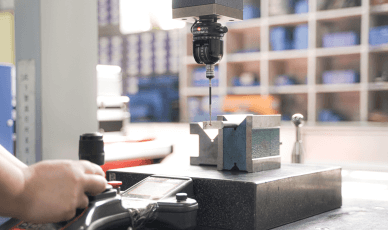

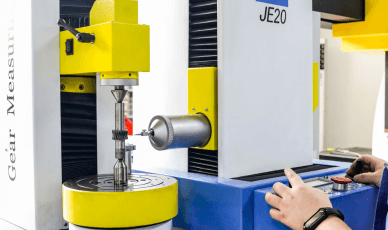

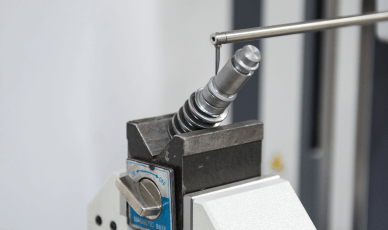

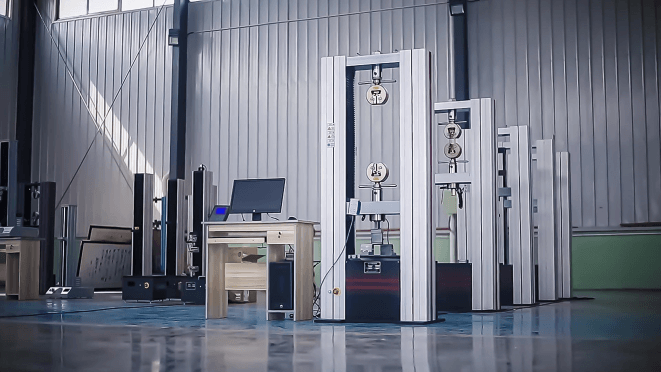

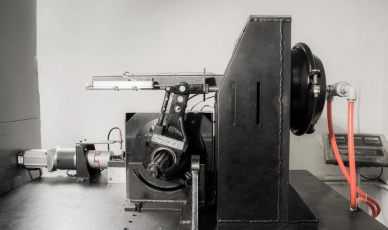

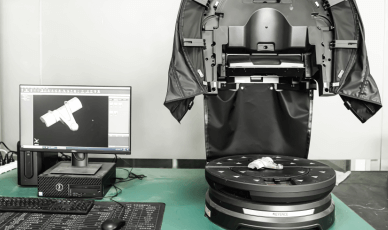

Roadage knows clearly that vehicle braking products are closely related to the safety of drivers. Thus, we pay much attention to our products' accuracy, and our powerful DMG Horizontal Machining Center finish the process from metal roughcasts to the different components of slack adjusters, creating the right shaped, grooves, holes, threads, among others by cutting the excess.

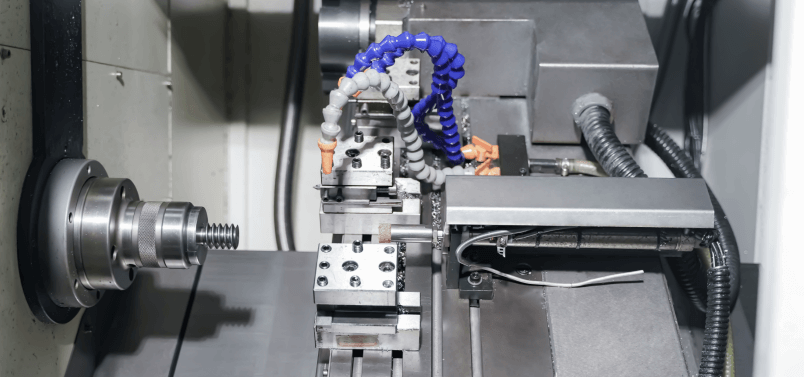

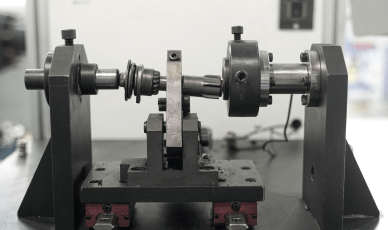

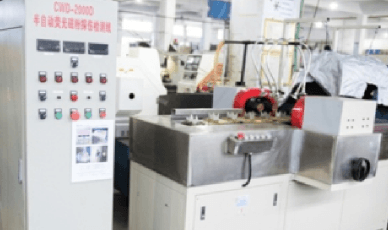

Assembly is the process in which technicians attach all the auto slack adjusters components to one another. Often times, the assembly is done by hand. However, in Roadage, it is finished by automatic assembly lines, which means high efficiency and stable quality of the final products.

Roadage is certified by the certification of the German TUV: ISO/TS16949 system. This means that we never compromise on our commitment to manufacturing vehicle braking products that is safe for drivers as well as the environment in our effort to create the most innovative and reliable vehicle braking products.

Slack Adjusters

Caliper Repair Kits

Brake Expanders

Home

About Us

Manufacturing

Blog

Contact Us